Our Services

Carpet Cleaning

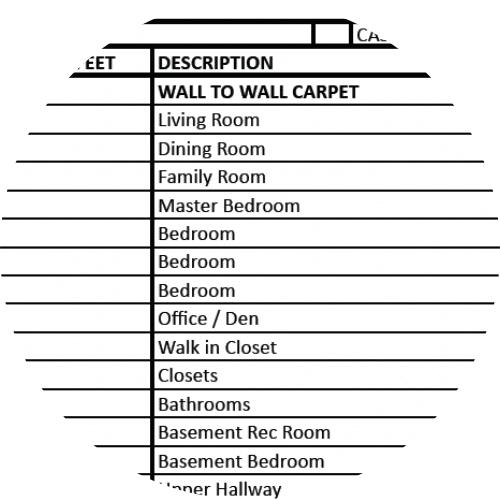

Maintain and love your carpet for life. Our expert carpet cleaning services will make your wall-to-wall carpet look and feel like new. Kashian Bros is the only local company that does its own cleaning. And we’re so transparent with our pricing that you can calculate the cost below. No hidden charges!

Deep clean your carpet with our professional steam cleaning.

Did you know that steam cleaning is one of the best methods to deep clean your carpet? Our professional steam cleaning not only reduces toxins and harmful allergens, it improves the overall appearance and lifespan of your carpet too. Our expert steam cleaning will help you love your carpet and home for life.We’re the local carpet cleaning experts.

Our professional technicians clean your carpet like it’s their own, taking extra time to thoroughly clean your carpet and remove stubborn stains at no extra charge. Our friendly team and reliable team will make sure you love your flooring and home for life. Always. Do you want your carpet to look like new? The Kashian Bros team can get you there.

Professional Equipment

We use the latest, top-of-the-line steam cleaning equipment.

Local

Expertise

Our technicians are trained company employees focused on your satisfaction.

Customer Satisfaction

Our seven-step process begins and ends with making sure your carpet looks like new.

Transparent

Pricing

We only charge for the actual size of the room, compared to many national companies that up-charge based on average room sizes.

We help you maintain your carpet and rugs in many ways. Check out our full list of services here.

Surround yourself with the things you’ll love for life. Check out all we have to offer.

Custom Carpet

Rug Cleaning

Vinyl Flooring

Check out what our customers have to say:

I have to congratulate your crew. I'm so pleased, my carpet looks so much better and I can't thank you enough.

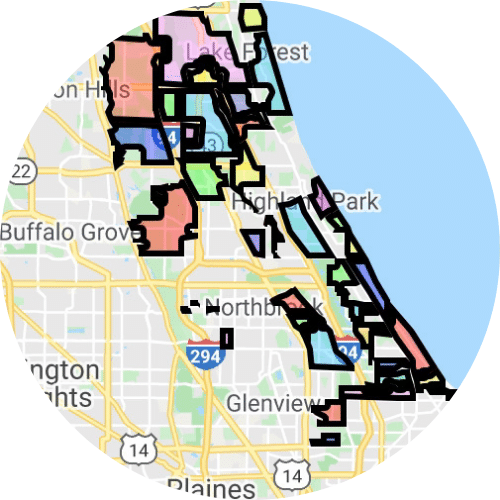

Mary D., Wilmette

They did an absolutely spectacular job [cleaning my chaise lounge]. They were very polite, very courteous. They worked quickly, and they really cleaned it.

Patricia B., Wilmette

I'm so happy with Kashian and everyone that I've dealt with there. Just wonderful to deal with and so professional. Absolutely hands down great people.

Michelle T., Chicagoland

I was really happy with the guys who did the [carpet and upholstery] cleaning in our house. They were neat, non-disruptive, and their work looks terrific. Really stellar job.

Bob D., Chicagoland

The carpet that was installed at our Lake Forest home is perfect!! The installer was great to work with also.

Jan G., Lake Forest